With constant threats of fire, gas leaks, equipment failure, and other safety hazards, the upstream oil and gas sector works in the most dangerous settings. Traditional safety equipment or procedures might not be very effective in these trying and important times to protect the crews from being impacted by these accidents. Thanks to technology, artificial intelligence, the Internet of Things, real-time monitoring, and automation, novel safety gear for the oil and gas industry is becoming the talk of the town or the need of the hour.

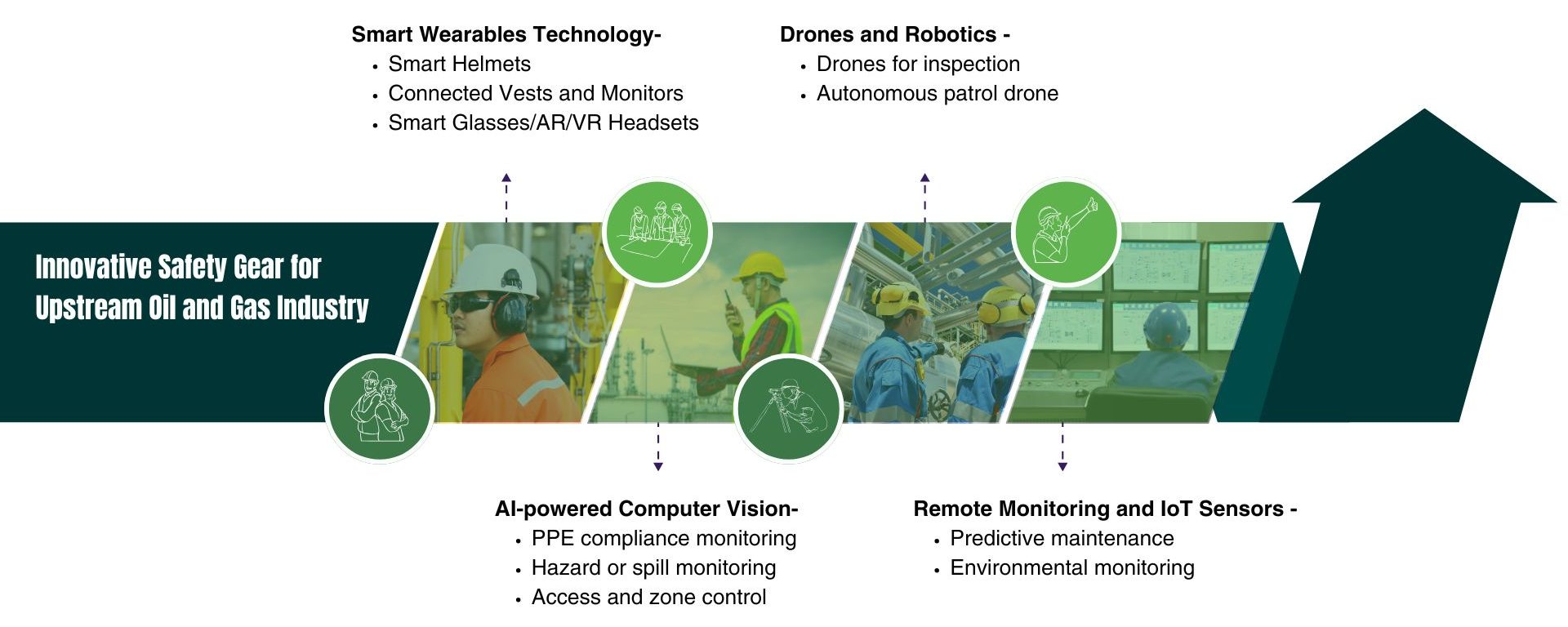

These improvements lessen human exposure to such hazardous situations, protecting against frequent occupational dangers. Here are a few examples of the quickly embraced technologies and techniques in use:

Selecting the right safety gear isn’t just about comfort—it’s about survival in extreme upstream environments where every detail counts.

Wearable devices with latest technology enhance efficiency on and off field by providing continuous monitoring of health conditions, location tracking and real time notifications to the field managers.

AI-enhanced video surveillance helps to keep a continuous check on the complex facility, something that is not possible through manual inspection routes.

In technologically equipped upstream oil and gas fields remotely controlled machines usually perform the high-risk functions with zero to limited exposure of people to areas of risk.

Remote monitoring by transmitting real time collected data from both the equipment on the field and the environment using low power, long ranging wireless protocols through sensors help detect downtime on a timely basis.

The upstream oil and gas industry will obviously always be a risky business, given its very nature, but the means of how to manage risk are changing dramatically. With the above-mentioned technologies, such as smart wearables, AI based surveillance drones and IoT sensors, in place, safety is not merely restricted to reactive; it is increasingly predictive and preventive. The automation and digital innovations keep workers out of these volatile areas while enhancing operational efficiency and minimising downtime. It means that regulatory compliance is being followed and that is why the demand for smart safety gear also has seen a massive jump. The upstream oil and gas sector is preparing for future-ready general operations that are resilient with improving people welfare and productivity.

By Get global | March 6, 2026

By Get global | March 3, 2026

By Get global | February 27, 2026

The oil and gas industry is complex and high-risk, making it essential for operators to select oilfield service partners based on more than just price or equipment availability. In the upstream sector—especially in the Middle East—Health, Safety, and Environmental (HSE) performance is now a key factor in decision‑making. Strong HSE […]

By Get global | February 24, 2026

Choosing an oilfield service provider rarely feels like a risky decision at the start. On paper, most providers look capable. Certifications are in place. Equipment lists are impressive. Commercial terms appear competitive. The problems usually show up later. A few weeks into operations. After the first unplanned shutdown. When coordination […]

By Get global | February 19, 2026

In today’s constantly evolving energy landscape, selecting the right Upstream Oilfield Services Provider is not only essential but also a strategic decision that directly influences the performance, safety and well being of the workforce. The upstream oil and gas sector operates in one of the most hazardous and risk – […]